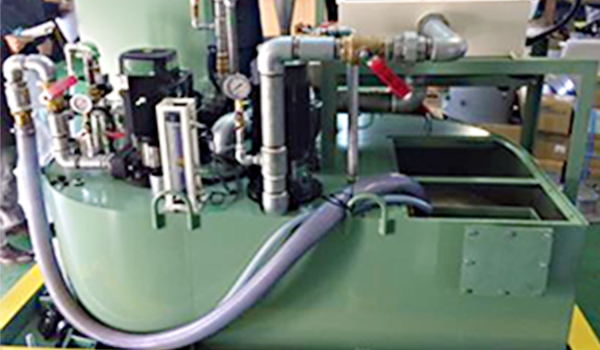

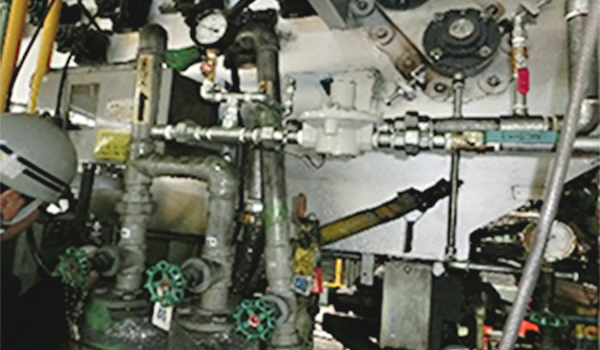

Comprehensive Contracting

We can carry out everything from design and specification proposal to construction and follow-up in precise accordance with client objectives for new constructions, renovations, safety measure construction and other projects.