High Mass Production Capacity

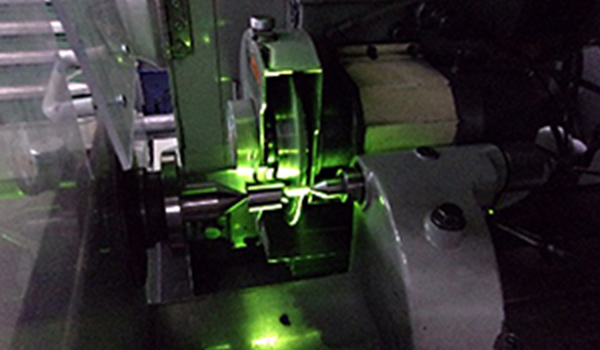

We have over 50 6-axis automatic lathes with a capacity to produce 16 million individual parts of various sizes per month.

We have two operation bases in Hanawa-machi, Higashi-Shirakawa-gun, Fukushima Prefecture, which are equipped with 6-axis automatic lathes which are mainly used for mass production of automobile related precision metal parts.

We can handle a wide range of client drawing requests by utilizing the knowhow we have accumulated through the processing of a wide and diverse range of products.

We have over 50 6-axis automatic lathes with a capacity to produce 16 million individual parts of various sizes per month.

By combining machines, we are also able to handle processing of shapes and degrees of precision which cannot normally be handled by a single 6-axis automatic lathe.

We also accept inquiries related to products which require post-machining heat treatment, barrel processing, and grinding processing through collaboration with affiliate companies.

Issue

Concerns regarding precision, shape, materials, material amounts, costs, etc.

Resolution

We can provide proposals for processing methods suited to client conditions.

(Maximum diameter: Φ35 mm)

We provide proposals tailored to customer requirements through coordination between experts in different divisions including those related to processing conditions, combinations of tools, cleaning, inspection, concerns about environmental burden, and more.

We strive to shorten delivery times and realize optimal quality as well as cost reduction through in-house production of some of the tools required for cutting processes.

We ensure high production capacity and precision for a long term by employing our equipment maintenance technologies which include lathe overhauls. We also focus on developing engineers who specialize in these tasks in order to further improve mass production capabilities.